Our Facilities

At Kudale Iron Works, our advanced infrastructure and commitment to excellence enable us to deliver top-quality engineering castings that meet the diverse needs of our clients.

State-of-the-art Infrastructure

Our state-of-the-art infrastructure includes two manufacturing units spanning 20,000 square feets each, with an installed capacity of 5000 metric tons annually. Equipped with advanced machinery, we ensure efficiency, resource optimization, and quality to meet bulk customer demands.

Foundry Units

We operate two state-of-the-art foundry units, equipped with advanced technology to produce high-precision gray cast iron and ductile iron components. Our foundries ensure:

- Consistent chemical composition

- Exceptional dimensional accuracy

- Superior surface finish

In-House Testing Laboratory

To maintain uncompromising quality, we have a fully equipped in-house testing facility for:

Chemical analysis

Dimensional inspection

Physical property verification

This ensures every casting meets industry standards and client requirements.

Brinell Hardness Testers

Universal Testing Machine

Spectro machine

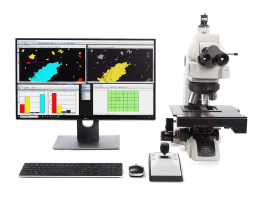

Image analyzer microscope Meta vision

Machining Unit KUDALE TECHNOCRAFT

Our dedicated machining unit, Kudale Technocraft, specializes in precision machining. With cutting-edge equipment, we meet the strict tolerances and specifications required for a wide range of engineering applications.

CNC Machine

VMC Machine

LATHE Machine

Flexible Production Capabilities

We offer production flexibility to handle both small and large batch sizes, catering to various industries with efficiency and reliability.

Skilled Workforce

Our team of experienced professionals ensures excellence across all stages of production, from design to final delivery.

With our robust facilities, Kudale Iron Works is committed to delivering high-quality, reliable castings that set industry benchmarks.